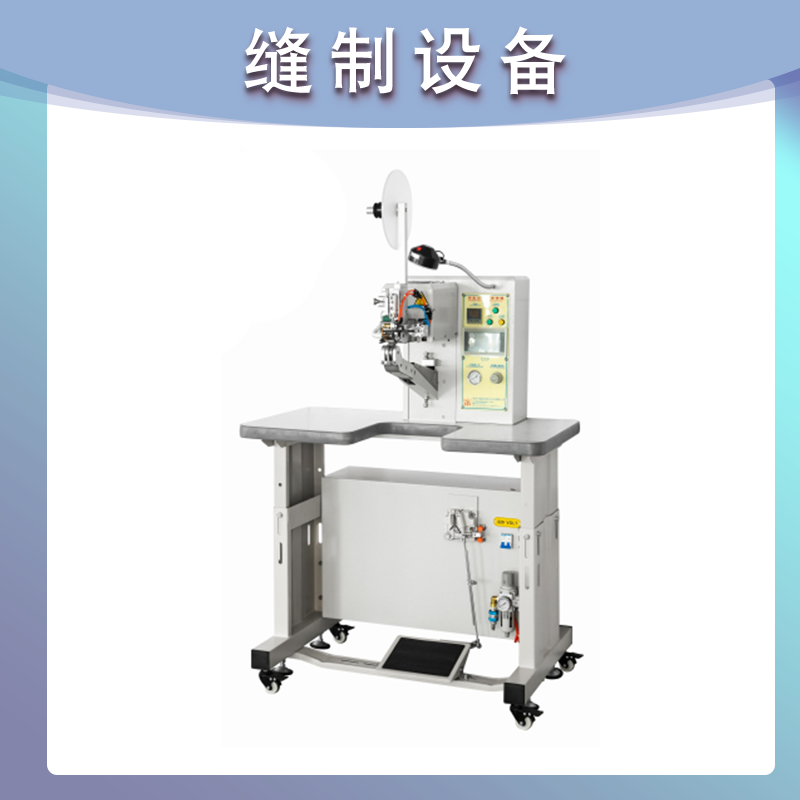

专为鞋厂、汽车工业及皮具制品厂而设计的一款全能机型,功能集合了制品车缝后的分边、捶平、贴带及布条剪切功能代旧式人手上胶、捶打、贴带的繁复工序,QC-850TX 智能分压布条机能一次性完成多项工序,节省人力和时间,又能提品质量。机器适用于布材、人革皮和各类真皮制品。设备功能:压合各类布条产品设备用途:适用于车缝部位分边压合电力要求:AC220V 50HZ160HZ功率:2000W

气压要求:稳定5kg/cm?熔接温度:温室-350°C

熔接速度:1-10M/分钟(可调)风枪规格:18mm可调扁口风咀

控制方式:PLC触屏逻辑控制

滚轮提起高度:30mm

电机数量:1组

净重:100KG 毛重:135KG机器尺寸:950*650*1600mm包装尺寸:1020*720*1420mm

Feature:

This all-purpose machine is specifically designed for shoe factories, theautomotive industry, and leather goods factories. lts functions include ed geseparation, flattening, tape application, and cloth strip cutting after theproducts are sewn. it replaces the complex processes of manual gluing,hammering, and tape application in the old-fashioned way. The QC-850TXintelligent edge separation and cloth strip pressing machine can completemultiple processes at one time, saving both labor and time, and improvingproduct quality, This machine is suitable for fabrics, artificial leather, andvarious genuine leather products.

Device Function:Pressing various cloth strip productsDevice Purpose:Suitable for edge separation and pressing of sewn partsPower Requirement:AC220V 50HZ/60HZPower:2000W

Air Pressure Requirement: Stable air pressure of 5kg/cm?Welding Temperature: Room temperature-350"CWelding Speed: 1-10M/min (adjustable)Hot Air Gun Specification:18mm adjustable flat-mouthed air nozzleControl Mode: PLC touch screen logical controlLifting Height of the Roller:30mm

Number of Motors: 1 group

N.W.(Net Weight):100kG

G.W. (Gross Weight): 135kG

Machine Dimensions (W*L*H):950*650*1600mmPackaging Dimensions (WL*H) 1020*720*1420mm